undefined

DALIAN HUARI METAL FORMING PLANT

Dalian Huari Metal Forming Factory has a complete technical development and production capacity from mold design, processing and manufacturing to complete sets of equipment. All kinds of machined parts, stamping parts, extrusion parts, tensile parts and welding parts produced by our factory are widely used in machinery, automobile, refrigeration, electromechanical, shipbuilding, construction, chemical industry, agriculture and forestry and other industries. The factory has also been identified as the designated manufacturer of spare parts by more than 30 foreign-funded enterprises, such as Sanyo, Toshiba, SMC, YANMAR, Ebara, Xizhi, Kawasaki Heavy Industry, SOUCY, OSHKOSH, and exported to the United States, Japan, Canada, New Zealand, Australia, Singapore and other countries.

Government Building

School

Factory Building

Dangerous Chemicals

Park Landscape

Office Building

Construction

Power supply

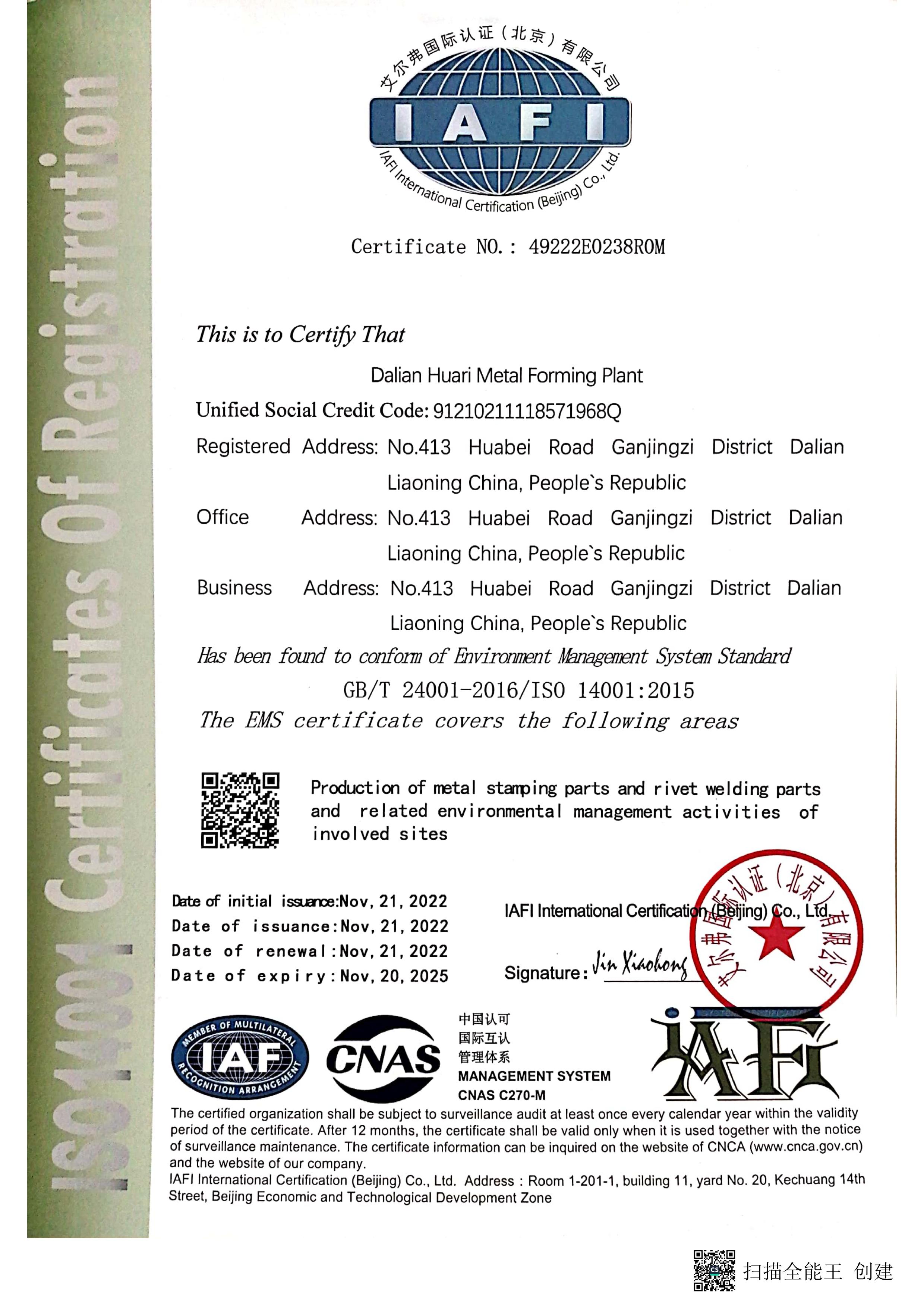

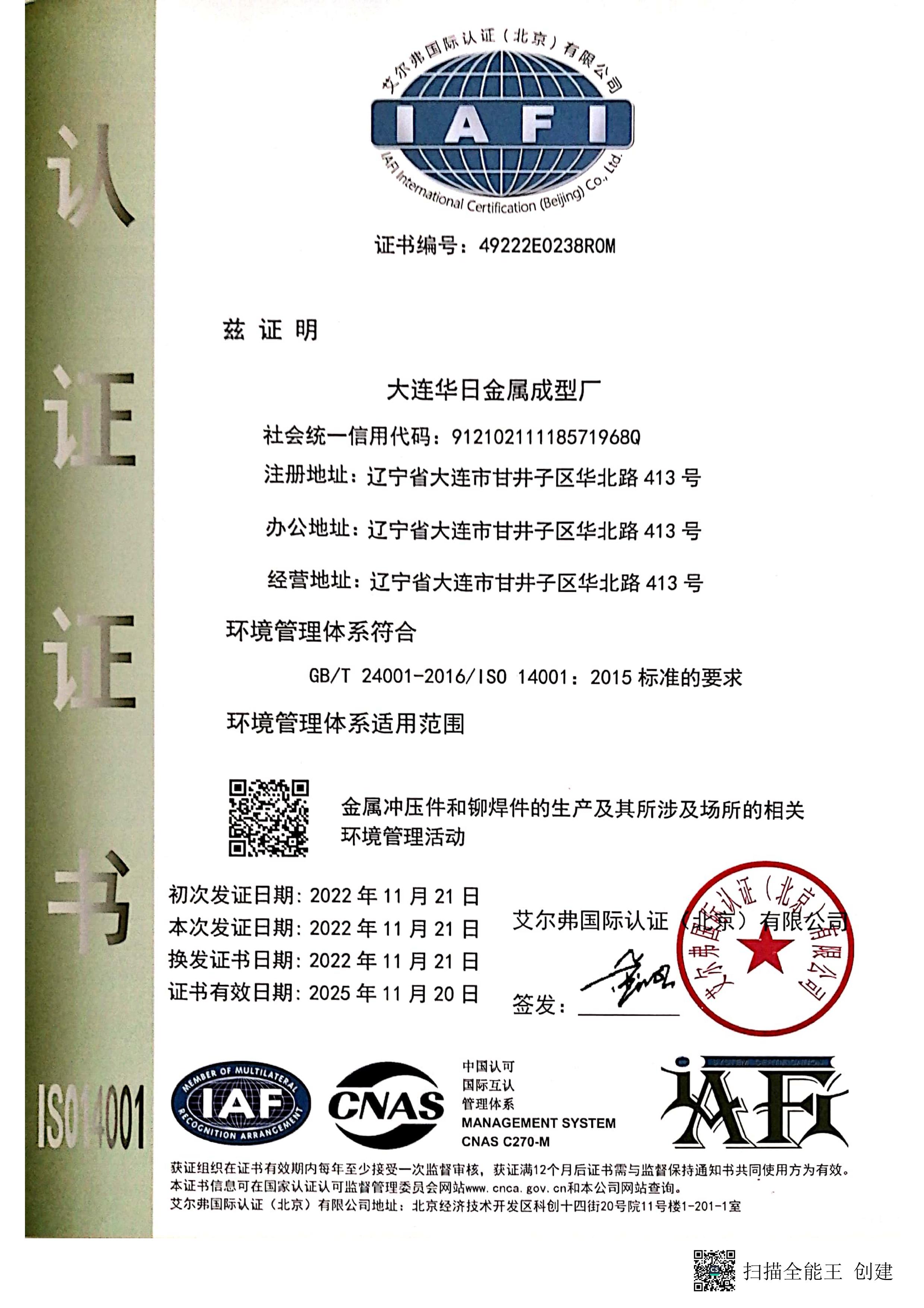

Qualification And Honor

Dalian Huari Metal Forming Factory is mainly engaged in the manufacturing and processing of metal products and sheet metal products, with a history of more than 40 years. Its products are widely used in agricultural machinery, engineering machinery, refrigeration and air conditioning equipment, vehicles, ships, machine tools and other fields.

ISO14001

IAFA

Quality Improvement Award

Build the brand image of China's metal forming industry

Build the brand image of China's metal forming industry

Advantages and disadvantages of different forging processes for metal materials

Forging is defined as the forming or deformation of a metal in its solid state. Many forging is completed by upsetting process. In the upsetting process, the hammer or striker moves horizontally to press on the rod or the end of the rod to widen and change the shape of the end. Parts usually pass through successive stations before reaching the final shape. High strength bolts are "cold headed" in this way. Engine valves are also formed by upsetting.

What are the common defects in castings?

Castings are metal shaped objects obtained by various casting methods, that is, smelting good liquid metal. By using casting, injection, suction or spray casting methods in other pre prepared molds, and cooling through subsequent treatment after grinding, the metal castings obtained will form a certain shape, size and product performance.

How is the metal hose pre compressed before installation?

The metal hose mainly has two stages: the bulging stage, in which both ends of the tube and the forming die are fixed, and the wall tube expands radially under the restriction of the die and the effect of the liquid pressure in the tube. The degree of bulging is relatively small, and its purpose is to make the forming die axially positioned on the pipe. In the two stages of forming, the tube is further bulged under the combined action of internal pressure and axial pressure.